Here at Wallace McDowall, we are committed to providing our customers with high-quality components. To ensure quality we use a BSI 9001 Quality Management System, this ensures that issues are found and eliminated at source. Our highly trained workforce work in all areas of our business auditing and controlling our processes and procedures, ensuring our customers receive a high-quality product. Our employees strive every day to ensure that we continually develop and improve the quality and efficiency of our processes.

Please contact us to discuss your project needs

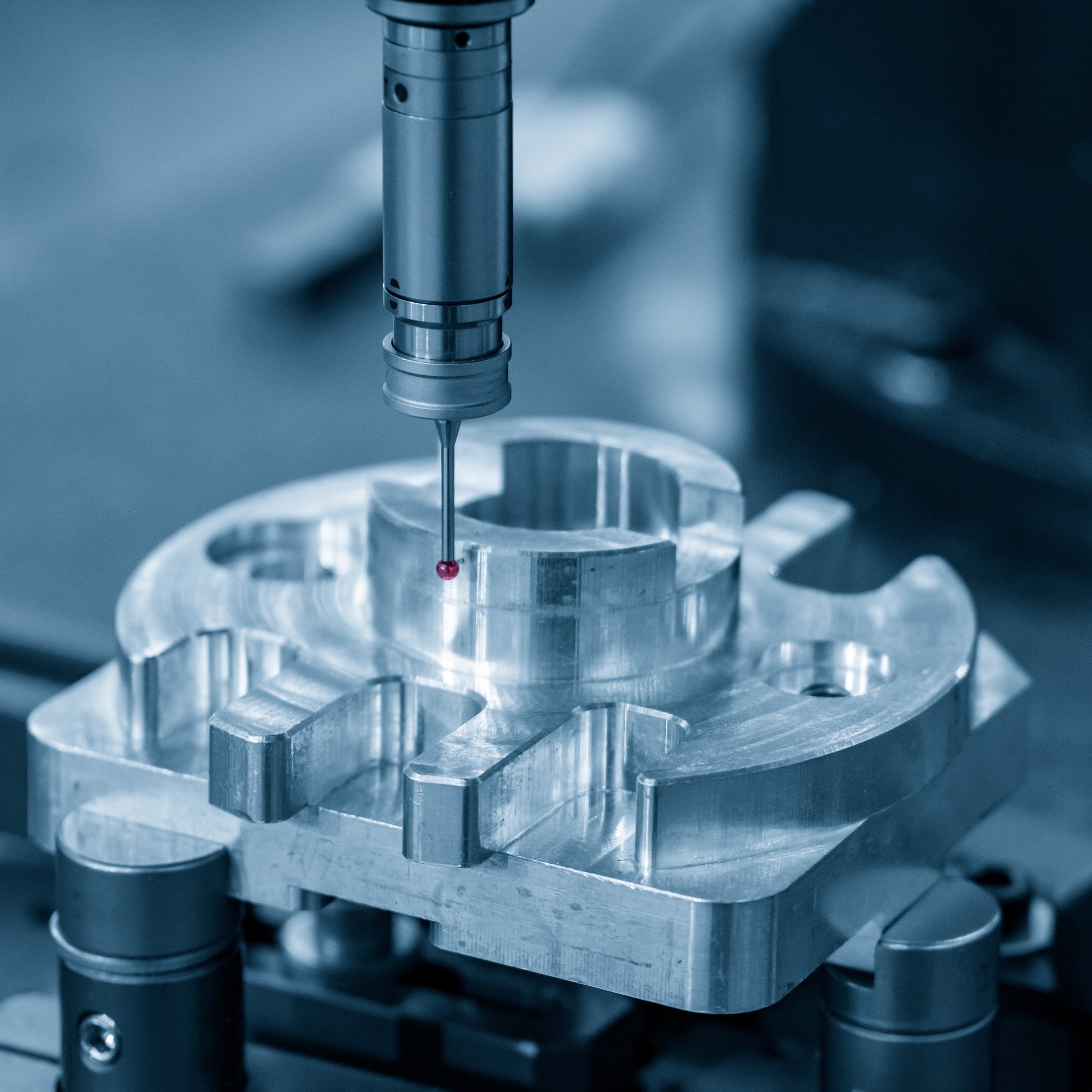

At Wallace McDowall, we have a vast array of equipment used to measure quality. This equipment ensures that we continue to provide our customers with high quality parts.

These include: